Up

Up

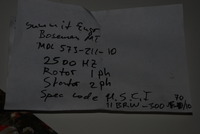

A while ago I mentioned this Troyke CNC rotary table that I bought on ebay for $149. This is something like 20 times cheaper, than a comparable Centroid (TM) rotary table like in this ad, but used. http://cgi.ebay.com/ws/eBayISAPI.dll?ViewItem&item=120587743949 http://igor.chudov.com/projects/Bridgeport-Series-II-Interact-2-CNC-Mill/24-Troyke-Rotary-Table-U12PNC/ It was described as "untested, as is", so I called the seller and spoke on the phone. My impression from him was that he was an honest person, so I bought this table despite it being AS IS. When I received it and applied power to the motor (30v, no more than 5A limited power supply) it would not budge. Called Troyke, they have NOTHING on it. I set it aside and continued to work on my CNC mill. Now that I have only a few odds and ends to do on the mill, like buttons and switches. They are complicated due to HALUI etc, so I wanted to do something easy. I looked at the table again. I took the motor off. Without the table, the motor spun happily. I stuck a bar into the table's motor connection (star type plastic force transmitter thingy) and tried to turn the table. After a little effort with a wrench, it moved. I found one more screw that might (not sure) have stopped the table, backed it out, and in any case, after a little while of rocking around the table felt much easier to move. It might have sat for 10 years or whatever and just got all stuck. Put the motor back and again, the motor would not move it. At this point I realized that 5A is just not enough to get it going. I called in in heavy artillery (military battery charger going up to 20A, 150V). Set it to 30 volts. When connected to that, the motor MOVED, and kept going. More voltage, more speed. I kept it running for a while (20 minutes or so). The running amps were approximately 3 amps. From that, the motor became warm, but barely, had a body level temperature. I explain this by assuming that the screw is preloaded or some such, and is hard to turn because Troyke tried to eliminate backlash. What I know at this point is that it is a DC servo driven table and it works. What I do not know is what is the operating voltage of this table. How would I find out? I am thinking, to take the motor out again (or take the rear encoder cover), and increase voltage until I get approximately 2,000 RPM from the motor. That should be appx. the max voltage. I do not really care with this table, to get max speed from it, as rotary tables do not often need to turn fast. I identified this resolver: Harowe Controls 11BRW-300-F10/10. It is still being sold for $1,423 apiece.

Long story short, I made the rotary table to fully work. It was much more time consuming than I expected. Everything needed a lot of time, thinking, I had to get this part or that, etc. At first I thought that I needed to swap the servo motor for somwthing like this, but then I got mine to work great. But at least it does work now. I had to get a better parallel port card, as the parallel card on the motherboard cannot handle more than four encoder outputs at the same time.