Up

Up

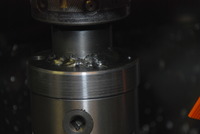

What I did was, I used a QC30 tool holder with a thick "neck" for a large diameter end mill, 3/4 or so, I do not remember. I took a round piece of steel, bored it on the mill to the diameter of the "neck", and drilled holes to bolt on the chuck. Then I put the bored round piece on the toolholder and welded it with 7018. It was not perfectly straight, as I expected. But then I put the toolholder into the spindle, spun it, and trued it as it was mounted, which, not surprisingly, gave an excellent result.