Clausing 6913 Lathe ==> Machining A Chuck

Up

Up

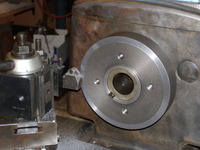

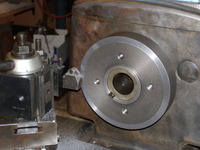

This page details how I machined a chuck to fit my lathe.

I bought a cheap imported chuck from Jeff Beck, who sells

cheap machine tool

accessories. Jeff is a

fantastic guy from whom I bought things in the past. He is very

customer oriented and always makes things right.

Anyway, what I bought from him was a L00

Four Jaw Lathe Chuck.

It had to be machined to fit the chuck to the backplate.

This is actually a good thing, because machining them on the

customer's lathe

can greatly increase accuracy of the chuck. Machining a chuck can

correct problems such as sligntly bent spindle or mars on the

spindle mating surface, for example.

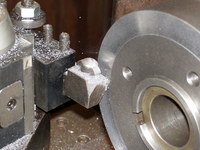

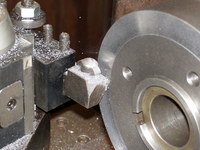

I did, essentially, three things:

- Machined the face. The point of this is to make sure that the

face surface is percisely located in the plane perpendicular to the

axis of rotation.

- Turned down the mating plug. The point of this is to make sure that

the chuck slips over it and yet is firmly centered. Here you want to be super careful and get tight fit, especially for three jaw chucks.

- Aligned the chuck body to point straight along the axis of rotation.

The issue is that the chuck's body is not perfectly machines and

it does not point straight, even though it is held tightly

against a perfectly perpendicular surface. The correction I did

was to insert paper shims between the chuck and the

plate. Before the shims, runout of a straight rod 10" out of the

chuck, was about 0.040". After the shims, I managed to get it

down to 0.004" (0.002" from zero).

(Click on the thumbnail images to enlarge)

Up

Up