Up

Up

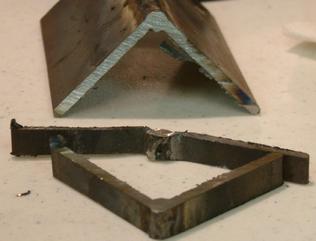

Today I tried to make some corner welds. I used 1/8" by about 1 5/8" strips of steel, which I cut with my chop saw. About 110 amps.

You will not see the terrible pictures of my first two attempts. If anyone is interested, I can take pictures. I tried using 6013 rod for inside welding and it was basically a complete disaster. The arc would not stay, would not get good root penetration, etc.

Roy and Wayne suggested that I make the following changes:

So, here you see the results of this. I cut off two slices of the resulting angle, and "unbent" one slice with a hammer, a little beyond even being straight, so that it is bent the opposite way. As you can see, it did not break.

Note that I used 7018 on the inside, and 6013 on ths outside.